Every Interaction

Has the Power

to Change a Life

Improve the Outcomes That Matter Most

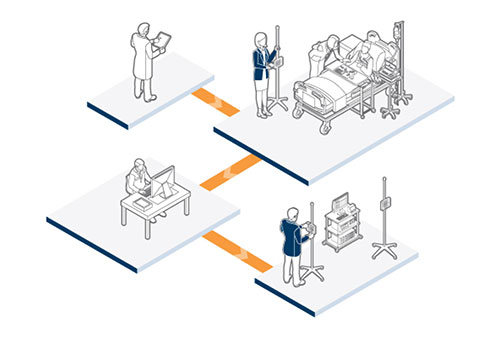

Hidden breakdowns in medical equipment management disrupt patient care and cost health systems millions each year. Discover how an end-to-end approach can reclaim wasted costs while ensuring caregivers have ready access to the patient-ready equipment they need.

Cut Costs Without Cutting Corners

From the OR to imaging departments to patient rooms, we ensure clinicians have immediate access to

equipment they need to treat patients — while measurably improving economic outcomes.

Medical Equipment Management

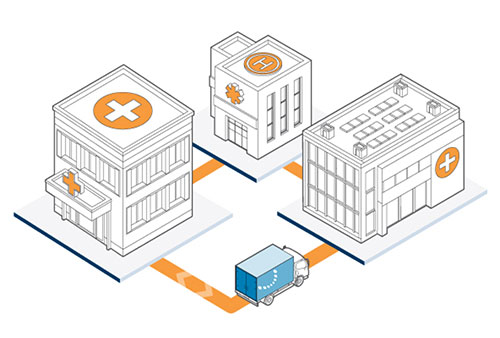

Medical Equipment Management

End-to-end equipment management strategies for hospitals, IDNs, OEMs and government – built through onsite managed programs and leading logistics services.

Medical Equipment Rental

Medical Equipment Rental

High-quality medical equipment rentals spanning critical care, surgical lasers and specialty beds and surfaces – delivered when and where needed in patient-ready condition.

DISCOVER EVM

Hospitals Nationwide are Reclaiming Millions in Wasted Equipment Spending. Here’s How.

Agiliti Insights

Success In The Modern Healthcare Environment Requires Agiliti